Research and engineering application of titanium alloy materials

Since its establishment, the marine titanium alloys developed and jointly developed by our institute include TA5, Ti-31, ZTi-60, Ti-70, Ti-75, Ti80, Ti-B19 and other grades, all of which have been applied in engineering and have won dozens of A national, provincial and ministerial science and technology progress award.

The main research areas:

New titanium alloy materials, titanium alloy welding technology, titanium alloy casting technology, titanium alloy near-net forming technology, titanium alloy forging and heat treatment technology, titanium alloy cold forming and processing technology, titanium alloy non-destructive testing technology

Titanium alloy industry

Relying on the titanium alloy industry developed by our institute's titanium alloy specialty, it has formed a series of titanium equipment and titanium alloy precision casting products including sponge titanium, which have been widely used in military and civilian fields, and the product quality enjoys a high reputation in the domestic and foreign markets. , The current annual sales exceed 500 million yuan, and the annual export value is tens of millions of dollars.

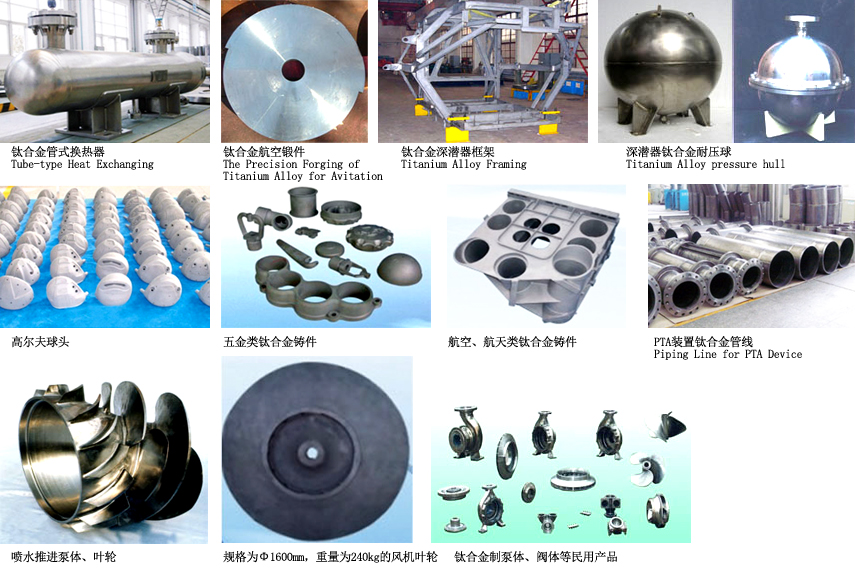

main products

deformed products:

Titanium alloy special structural parts, shells, seawater pipe systems, etc., titanium alloy tube heat exchangers, titanium alloy plate heat exchangers, chemical PTA devices, titanium alloy pipelines, aviation titanium alloy castings, and forgings

casting products:

Titanium alloy golf head blanks, human titanium bones and prosthetic parts, titanium alloy bicycle parts, titanium alloy precision casting hardware, machined graphite titanium alloy castings, titanium alloy castings for aerospace, titanium alloy castings for ships, spray Water propulsion systems, propellers, impellers, etc., chemical corrosion-resistant pumps, valves, etc.

Industry status of titanium alloy products industry

Our firm is the executive member unit of the National Titanium and Titanium Alloy Academic Committee; the standing director unit of the Titanium, Zirconium and Hafnium Branch of China Nonferrous Metals Industry Association. Editor in chief of more than ten titanium alloy material standards and welding standards, has been engaged in the scientific research and production of titanium alloys for more than 40 years, has the domestic first-class titanium alloy materials and process research capabilities, and has independent intellectual property rights for special marine titanium Alloy equipment manufacturing technology and titanium alloy precision casting technology, the products have reached the international advanced level. The technological level of titanium and titanium alloy welding and titanium alloy castings is in a leading position in the country, and a manufacturing base for ship titanium alloy equipment has been established.

Titanium alloy deformed products production capacity

Titanium alloy deformed products base, covering an area of 10,000 square meters, has domestic advanced four-roller coil forming machine, computer simulation moldless multi-point forming equipment, large-scale vacuum annealing equipment, and has the domestic leading titanium alloy automatic gas shielded welding, Plasma welding, narrow gap welding, cold arc welding, tube sheet automatic sealing welding, temperature and humidity controllable assembly welding and other equipment, with dedicated titanium alloy product clean workshop, various non-destructive testing and heat treatment methods, deformed titanium alloy production line; can be produced Various types of titanium equipment and structural parts have a production capacity of 200 to 500 tons per year.

Main production workshops and equipment:

Production capacity of titanium alloy casting products

The production base of cast titanium alloy products covers an area of 40,000 square meters. It has multiple complete cast titanium production lines. Its mold shell preparation and vacuum casting technology are of international advanced level. It can produce a diameter of 2m, a height of about 1.5m, and a single piece of weight. 800Kg of titanium castings and precision castings with a wall thickness of 1mm up to 0.8mm locally. The golf heads and human prosthetic parts produced are sold all over the world, with a casting production capacity of 1,000 tons per year. It is one of the main professional production bases of titanium alloy castings and products at home and abroad.

Main equipment and workshop:

VAC1000 vacuum consumable electrode condensing furnace

Asia's largest vacuum consumable electrode condensing furnace, the maximum melting capacity of titanium liquid: 1000Kg, this equipment is mainly used for vacuum melting and casting of titanium alloy electrodes, is one of the most critical equipment to determine production capacity and ensure qualified products.

The main technical indicators are as follows:

Ultimate vacuum: 6.7×10-2Pa

Working vacuum: ≤1Pa

Centrifugal speed: 0~400 rpm

Maximum melting capacity: 1000Kg

Maximum melting current: 60000A

Standard electrode size: Φ160~380mm

Maximum mounting surface: Φ2200mm×2500mm

Maximum casting volume: 800Kg

DHL650 vacuum consumable electrode melting furnace

is mainly used for the smelting of titanium alloy electrodes, and is one of the most critical equipment to ensure qualified products.

The main technical indicators are as follows:

Ultimate vacuum: 6.7×10-2Pa

Maximum melting capacity: 650Kg

Smelting electrode size: Φ100~240mm

Smelted titanium ingot size: Φ150~380mm

Maximum working current: 12000A

Titanium alloy products

Shuangrui Group

Luoyang SunRui Plastic & Rubber Technology Co., Ltd.

Lepu Medical Technology (Beijing) Co., Ltd.

Luoyang SunRui Special Equipment Co., Ltd.

Luoyang SunRui Wind Turbine Blade Co., Ltd.

Luoyang SunRui Precision Casting Titanium Industry

Co., Ltd.

Luoyang SunRui Wanji Titanium Industry Co., Ltd.

Luoyang SunRui Metal Composite Material Co., Ltd.

Luoyang SunRui Real Estate Development Co., Ltd.

Luoyang Seven Star Technology Trade Co. Ltd.

Links

Webpage Copyright(c)1999-2006 CSSC Group Corporation No. 725

Research Institute

豫公网安备41031102000713

豫ICP备13020589号-2

Powered by:Bluewave.com.cn